In this article

When an ordinary bearing just won't wash

Washdown is a blessing and a curse for food manufacturers. A blessing because it blasts away bacteria that can bring production to a standstill. A curse because hot, humid conditions combined with pressurised water can play havoc with bearings that are critical to machine performance.

Under washdown’s harsh conditions, water and detergent can penetrate bearing seals – leading to damaged lubricant, reduced bearing life and, if not properly managed, catastrophic machine failure.

Potentially even more serious is the risk of lubricant leakage from the bearing housing, which could contaminate products. At best that can cause a line stoppage, and at worst a product recall.

So the dilemma for food manufacturers is how to maintain hygienic conditions while maximising machine performance? One solution is to use specific food-industry bearings.

Good enough to eat?

Bearings developed specifically for food production are made from food-grade materials, are designed to prevent bacterial growth, and are easy to clean. There’s a price premium compared to a standard bearing, but that’s balanced by more efficient running and longer life.

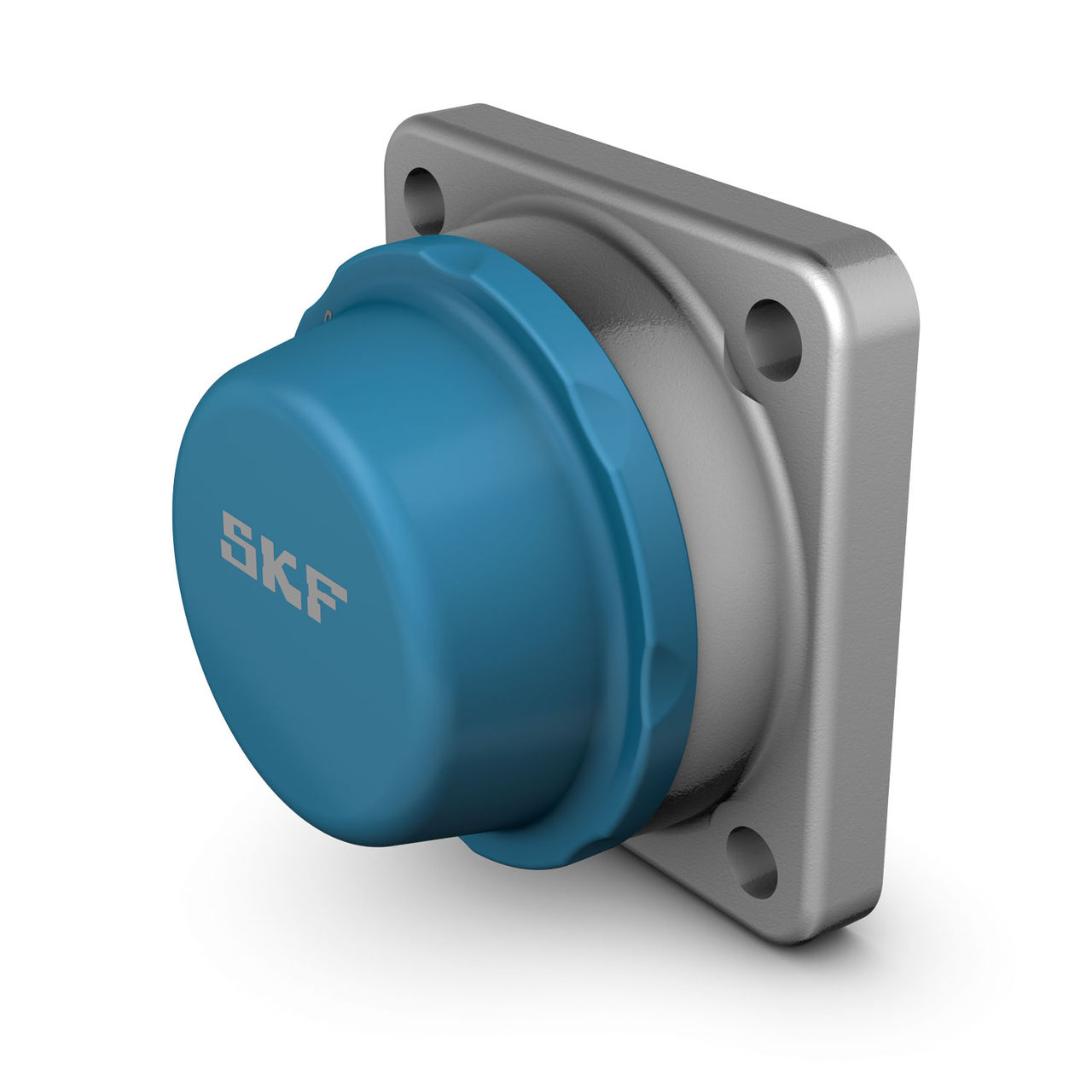

SKF’s Food Line bearings, for example, help food manufacturers incorporate hygienic design principles while maintaining performance, cost and sustainability. And even in punishing environments, their special design helps to eliminate contaminants and reduce the spread of bacteria.

Firstly, they meet food safety and compliance regulations. These require food-grade materials for the bearing and internal lubricant, and features to help food manufacturers operate efficiently – whether through maintaining cleanliness, or making cleaning and maintenance easier.

Correctly designed bearings for the food sector can also cut costs and enhance sustainability

Higher hygiene

A high standard of hygiene improves food safety and reduces product recalls and line shutdowns. And specially designed bearings can be critical in addressing these specific food-industry challenges.

For example, angled surfaces promote self-draining and resist soiling, whatever the mounting orientation. SKF Food Line bearings are engineered to have no ‘dead spaces’ which could harbour bacteria, as well as featuring smooth surfaces to help make cleaning more efficient.

Bearings that are easier to clean are also cheaper to clean. Cleaning a Food Line bearing, for example, needs around a third less hot water than for a typical bearing: so both energy costs and carbon footprint are reduced.

Beating bacterial build-up

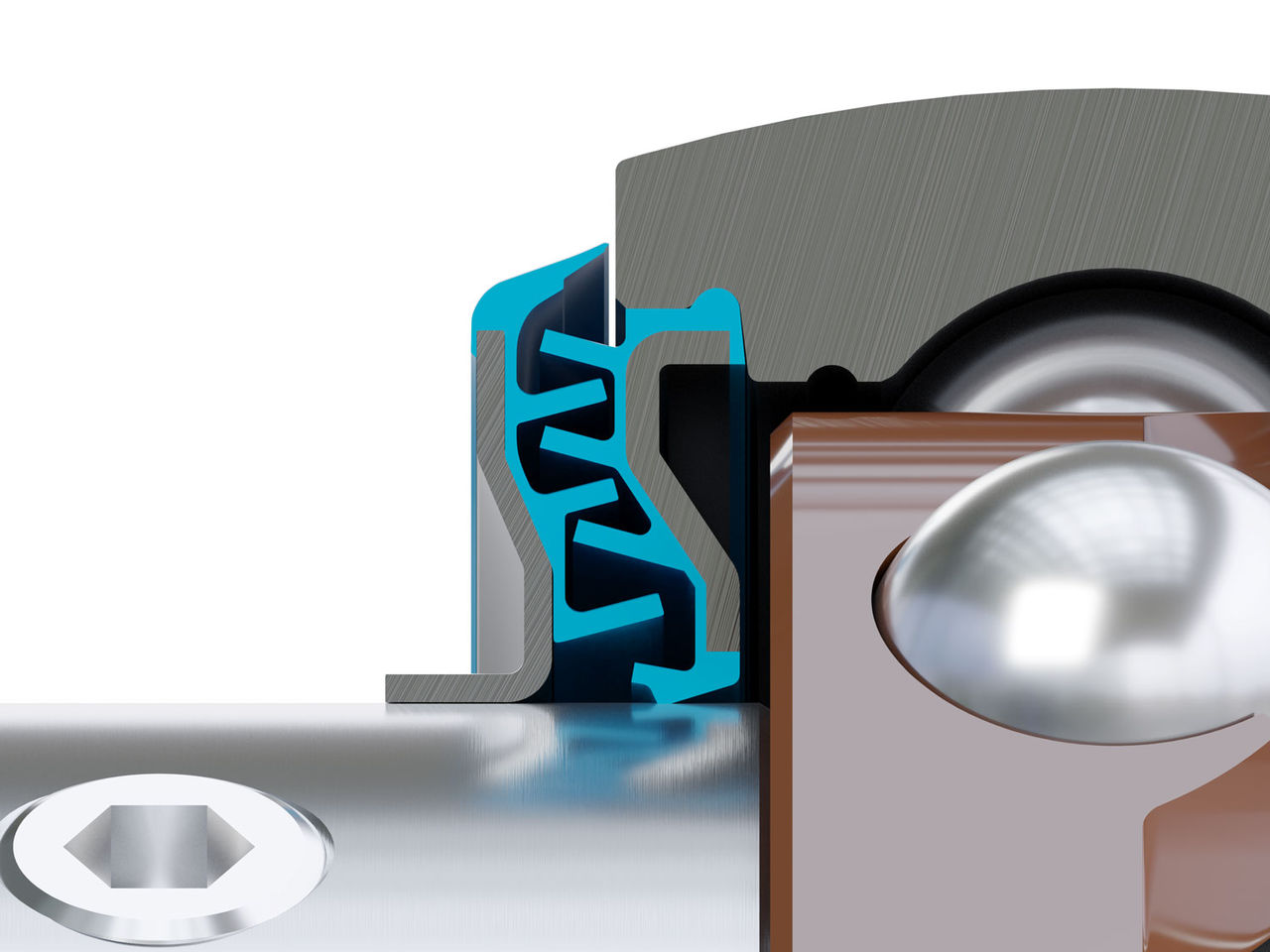

A critical feature of SKF Food Line bearings is a patented, four-element sealing system that reduces bacterial build-up.

Firstly, a base seal is formed when the bearing is fitted to the mounting frame. Secondly, a back seal stops material entering the bearing cavity from the back. Thirdly, the housing is designed to eliminate crevices and recesses where bacteria might accumulate. And lastly, an end cover held in place by a patented locking mechanism seals the unit completely.

The bearing, base and back seals are all made from food-grade, FDA- and EC-compliant synthetic rubber. Housings and end covers meet FDA regulations, and the food-grade bearing grease is allergen-free and approved for accidental food contact. It also complies with Halal and Kosher certification.

As an extra food safety feature, the seals and housing material are coloured blue, making visual detection easier if accidental contamination is suspected.

Get into the groove

Deep groove ball bearings have generally only been available as a ‘custom filled’ product. But SKF recently introduced an off-the-shelf version specifically for the food industry, with an integral seal to reduce water ingress, enhance bearing performance and optimise hygiene.

As an off-the-shelf product, it’s faster and more cost-effective to re-order. And being produced to SKF’s Explorer performance class standards, it has a high load-carrying capacity that maintains rotating equipment performance.

Just like SKF Food Line bearings, the deep groove version complies with food industry standards – with food-grade NSF H1 grease, Halal and Kosher certification, and US Food and Drug Administration (FDA) and European Community (EC) compliance.

With no relubrication required, maintenance is reduced, uptime increased, risk of leakage reduced, and grease consumption cut. And of course there’s no waste grease to dispose of, so it can even contribute to a 0% landfill policy. Eliminating relubrication also helps to stop excess grease accumulating in end covers, where bacteria typically grow.

Washdown can be tough for bearings. But SKF’s specially designed food industry versions can take it. And give you longer life, no lubricant leakage, reduced bacterial growth risk, increased efficiency and improved hygiene too.

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SKF #ERIKS #LetsMakeIndustryWorkBetter #Bearings #Food #FoodSafety