In this article

ERIKS and SAI Automotive Fradley OnSite

Lee Matthews’ relationship with ERIKS goes back a long time to 2002 when the site he was working at in Coventry was moved into the current site in Lichfield Lee took ERIKS with him.

At that point ERIKS scope of business with SAI Fradley covered a wide range of products (including office supplies!) – but was a traditional, arms-length, distributor/customer relationship. That changed fundamentally with the move from Coventry as ERIKS came ‘Onsite’ with a team of 2 people and began working on engineering solutions and maintenance spare parts and becoming the all-round service provider to SAI Automotive Fradley which they remain to this day.

In 2007 Lee’s relationship with ERIKS changed again when he took responsibility for NPP (Non-Production Purchasing) and became the Maintenance and Engineering Manager and started to develop a mutual set of KPIs. “Cash was important for me, and I wanted to work on a consignment stock basis as well as looking at delivery and lead time” he says. Lee is currently the Plant Manager and has been the for the past four years and his relationship with ERIKS has changed beyond recognition.

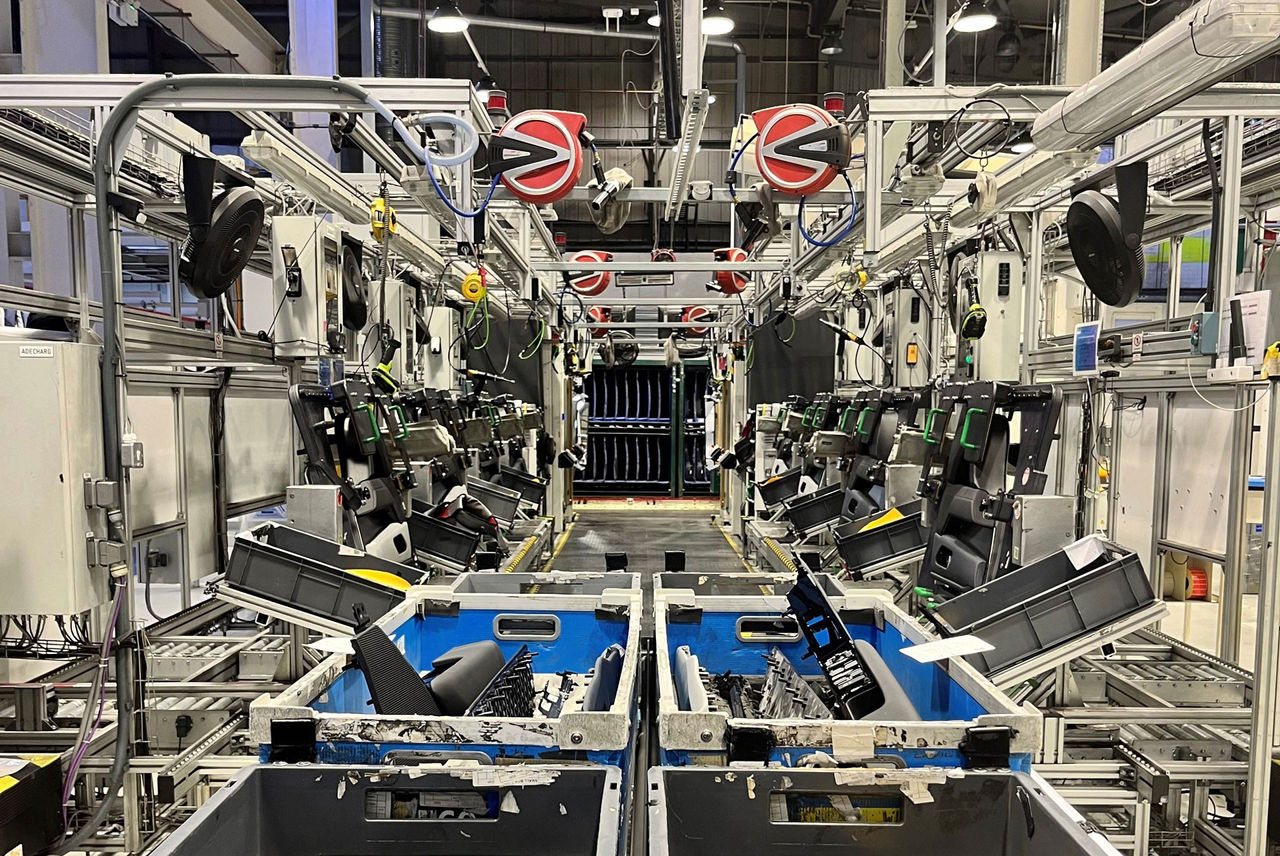

As he says himself, “In the past my relationship with ERIKS was almost 24/7. I could call them and say I need some help and this for me was the important thing about ERIKS, they understand our business, they grew with us from being just a consumables supplier to being an all-round service supplier. Our business is Just in Sequence (JIS*) and we make £150 million in sales in the automotive industry.”

“Our main customer is JLR (Jaguar Land Rover) and we make door panels from granules to a finished door set within a six-hour window. We cannot hold up JLR production as that has significant cost implications – between £30,000 and £80,000 per minute! Fortunately, there have been virtually zero instances when that has happened in my time and ERIKS has played a key part in that.”

Personal relationship

During his time as Maintenance and Engineering Manager Lee had cause to call on ERIKS on many occasions, even over weekends and holiday periods, to ensure he met the demands of his highly exacting customers. “This relationship was very, very important to me and I still have a personal relationship with the people I worked with at that point even though, ostensibly, I don’t work with them directly in my current role.” says Lee.

But while Lee has a long history with ERIKS and has established strong bonds with the people he worked with over the years there’s no chance of his viewing ERIKS as his only option. “I’m very fickle, you are only as good as your last mistake” says Lee “the door was opened many times and, on some occasions, competitors have been able to match or better ERIKS in some areas, piece price or some such, but they didn’t offer the fully integrated solutions that you get with ERIKS.

I could get some things cheaper, but I couldn’t get the full service. I force my ME [Maintenance and Engineering] manager to do his due diligence and to assess the market and the competition ensuring there is no monopoly, but I have never seen such an integrated solution from ERIKS’ competitors.”

Key performance

The services which SAI Automotive Fradley receives from ERIKS are governed by a set of operational and commercial Key Performance Indicators (KPIs) that have evolved throughout the relationship. These KPIs are reported monthly and include:

- Inventory levels - where the two businesses are looking to reduce the stock which SAI Automotive holds through a mixture of increased consignment stock and moving on stock which is over two years old

- Stock count – where ERIKS conduct perpetual stock counts and stock reconciliation to maintain accurate stock level records in the SAP system.

- Stock accuracy – currently operating above 98% and with a focus on documenting obsolete stock which can be offered to other plants in the group or otherwise be scrapped.

- Delivery performance – Of over 500 items delivered in a given month those recorded as ‘on time’ represented between 91 and 96%.

- Savings – ERIKS continuously identifies where high impact savings can be achieved through negotiation, resourcing or product substitution.

- Carriage – ERIKS continues to minimise carriage charges through grouping orders together when dispatched from the FCE and challenging suppliers on excessive costs.

Additional extra services include many that focus on the industry-wide headache of energy. An air leak surveys project has enabled the plant to reduce the operating pressure of its compressed air delivery system. “This has saved me a huge amount of money” says Lee “and we have also done another project where we looked at the chiller drive pumps. ERIKS identified the opportunity and presented it as a turnkey project which again has proved successful in reducing energy demand and generating cost savings. Drive replacement was another similar example and energy prices now are such that these conversations are being had regularly between us - their pro-activity is appreciated.”

Communication

The level of communication between the ERIKS OnSite team and Carlos Mendonca, the Maintenance and Engineering Manager, is constant. “In my day” adds Lee “there was a morning Top 5, we would ensure that all the jobs from the previous day had been dealt with and lay out the priorities for the coming day.” says Lee.

“We have a monthly meeting to discuss KPI’s” says Andy Gibson, ERIKS’ OnSite team leader “we also have a weekly meeting with Carlos to discuss ongoing requirements and issues and to discuss what I need from him and what he needs from us.”

When asked about ‘showstopping anecdotes’ Lee’s reaction is revealing. “To be honest, I would find it impossible from my time as the ME manager to give you any individual stories about when ERIKS went above and beyond to save my bacon because of how many times it happened. In this sector, with this business it’s a weekly or monthly occurrence.

And this is exactly what I did not see in the competitors I did not see this commitment to service or level of technical knowledge or competence. They couldn’t convince me that they could match what I had already seen and experienced.”

“It’s what we are there to do” adds Andy Gibson “It’s just what we do”.

The ability of ERIKS to come to Lee’s assistance with sourcing replacement parts within a short time frame or advise on an engineering solution is what he believes is the difference. “I would send a video or a photo to the ERIKS team saying I have a pump breaking down and a picture of the plate and within a few minutes I would get a response saying ‘this is the make of the part and we can get it from here, here or here and this is the lead time and this is the cost which option would you prefer and do you want to fly it do you want to or get it by taxi or courier?’ This is the sort of service I am used to.”

Challenges

“We have had an instance like that just this week” says Andy Gibson. “I am on a WhatsApp group with the maintenance team, and they sent me a picture of a motor which was failing, and we sourced it, and it was delivered before 9am the next morning. When I spoke to Carlos yesterday, he was pleasantly surprised that the replacement motor had already arrived!”

One of the more recent challenges which Andy has been working on with Carlos relates to the challenges which Brexit has thrown up around importing spares from mainland Europe. “We have been looking at min/max levels because of these challenges” says Andy “We are having to re-set these and increase them for some items. They were all set pre-Brexit before the challenges of getting them through customs in a speedy manner occurred.”

“Brexit for me has caused quite a bit of frustration” says Lee “we had to change our strategy somewhat, we had to put in additional redundancy in equipment and additional safety stock in parts and I have had to increase my cash tied up in stock and my CAPEX to purchase that buffer stock significantly to cope with the new set of circumstances.”

Lee is, as ever, keen to ensure that as much of the stock on site is there on a consignment basis to free up his cash flow and this is worked out between the two parties on a percentage basis. Andy provides more detail, “We have a healthy amount of consignment stock on site and it’s my job to make sure it’s re-ordered on time, and I am currently reviewing slow moving stock that has not moved for 12 months. There’re about 600 items in consignment stock and 90% of it moves within a 12-month period so it’s current and effective consignment stock.”

Tactical projects

One development recently put in place by SAI Automotive Fradley is the introduction of the Agilon storage system from Konecranes. “It’s a modular, robotic vertical storage system that weighs the parts and is good for my inventory accuracy and therefore saves time for my team in terms of stock counting” says Lee “but someone has to feed that, so I understand that ERIKS have to load items into the system every time we get a delivery which has increased their workload. But this has helped prevent stock outs of the 4800 items in the system and keeps track of who is taking each part.”

“Slow moving stock has not been moved into the Agilon system” says Andy “we keep that in another area and that has led to good stock management.” Looking to the future there are several tactical projects on the horizon. “We have been looking at the motors on the injection moulding-machines and will be installing IE4 motors soon.

These will be more energy efficient. Plus, we are looking at all the filters on the site.” says Andy, “It’s a high use product and the prices have increased considerably in the last few years, so we are hoping to address that through alternate sourcing. We are just about to bring some samples in and, if they work, we’ll begin to introduce the new products”.

“On a strategic level” continues Lee “we are looking more widely at energy management and CO2 reduction. An example is where we are replacing the free air chillers, with the funding being provided by a Venture Capital business, and this will be paid for through the energy savings which again will increase the work with ERIKS. In the same way we are looking at heat pumps, photovoltaic cells and anything to do with energy management.

Long relationship

“I am very passionate about this relationship” says Lee “I brought ERIKS across with me and I feel like I was instrumental in making sure the relationship was successful and throughout I have been open and straight with them about assessing the competition to ensure we are getting the best service for the business and that my personal opinion is corroborated by an open market assessment and comparison.

An important reason for continuing to work with ERIKS is that today, if my ME manager has a problem, and Andrew cannot solve it, I know my senior contacts at ERIKS and - if it reaches that level and I am involved and they are involved - then it’s serious and they will pull out all the stops to make things happen. I know they will work to the best of their ability to solve my issues.”

“The longevity of the relationship and the hard-earned trust that has been developed are key” summarises Lee.

Notes:

SAI Automotive Fradley Limited designs and manufactures instrument panels, center consoles, door panels and door modules, and acoustic modules. The Company offers many solutions in a wide range of key areas including weight reduction, cost control, decoration, perceived quality and control.

*JIS - Just-in-sequence (JIS) inventory management is a variation on JIT. The main differentiator between just-in-time and just-in-sequence (JIS) is that JIS ensures inventory arrives in the specific order in which it is used in production.

Are your stores keeping you awake at night?

ERIKS supply chain and inventory knowhow can help release time and capital caught up in your indirect or maintenance, repair and operations OnSite supply chain.